Self-Tapping Inserts

- Home

- Self-Tapping Inserts

Stainless steel self-tapping inserts

Our external self-tapping thread forms are unique to our blind and through tapped insert range. We’ve invested in tooling specifically made for us, so consistency in function and appearance is guaranteed.

We hold stock of stainless steel inserts in A4, A2 and brass and can also custom-manufacture to drawing or specific dimensions.

Our blind form inserts (IBS range) are ideal for marine use or in any applications where a waterproof fit is required and water ingression along the internal thread could be an issue.

Through tapped form (ITS range) are ideal for applications where there is clearance behind the insert, so bolt length is not critical.

Our insert range has been carefully designed to fit flush when installed, with the addition of an undercut and countersunk head.

Features of our self-tapping inserts:- Suitable for use in wood, composites, plastics and some soft metals.

- Can be screwed into a pre-drilled hole or bonded/ moulded into place.

- Supplied in regular or heavy-duty form with a coarse self-tapping thread, larger external diameter, longer length and V shaped flutes at 120-degree intervals for additional grip when bonded.

- Available in a range of internal threads, metric and imperial. Can be made to specific customer requirements.

- We also manufacture the more generic slotted style self-tapping inserts with finer external threads, more suited to use in metals and harder materials.

Thread Repair Inserts

- Suitable for use in wood, composites, plastics and some soft metals.

- Can be screwed into a pre-drilled hole or bonded/ moulded into place.

- Supplied in regular or heavy-duty form with a coarse self-tapping thread, larger external diameter, longer length and V shaped flutes at 120-degree intervals for additional grip when bonded.

- Available in a range of internal threads, metric and imperial. Can be made to specific customer requirements.

- We also manufacture the more generic slotted style self-tapping inserts with finer external threads, more suited to use in metals and harder materials.

Thread Repair Inserts

Also known as thread reducing inserts (ITR). These inserts are similar in form to our IBS/ ITS inserts but feature standard metric or imperial internal and external threads in any combination or length required, both blind ended and through tapped.

We also produce an unheaded range, which allows you to screw the insert as far in as you need to give a little more flexibility with the application.

Ideal as a solution to stripped or damaged threads where the damaged hole can be drilled and re-tapped.

Custom-made stainless steel inserts

All the stainless steel threaded inserts we produce are manufactured from high-quality 303 or 316 stainless steel.

Our range also covers a heavy duty stainless steel inserts which have a slightly larger external diameter and longer length, designed to give more surface area of thread and a greater 'pull out' resistance. We add three deep V-shaped flutes which is added with bonding in mind to give space for the resin of glue to harden and assist with the cutting action of the thread upon insertion.

Join our growing list of happy customers

Don’t just take our word for it—read what our customers say about Bon Precision Engineering. Our reputation and integrity mean everything—and we are proud to have received some great feedback from our customers.

Contact Us

“I've worked with Bon Precision both commercially and as a boat owning aficionado and can't recommend them highly enough.Their desire to fulfil your every requirement is legendary, complimenting perfectly their refreshingly efficient despatch and delivery times. A joy to do business with.”

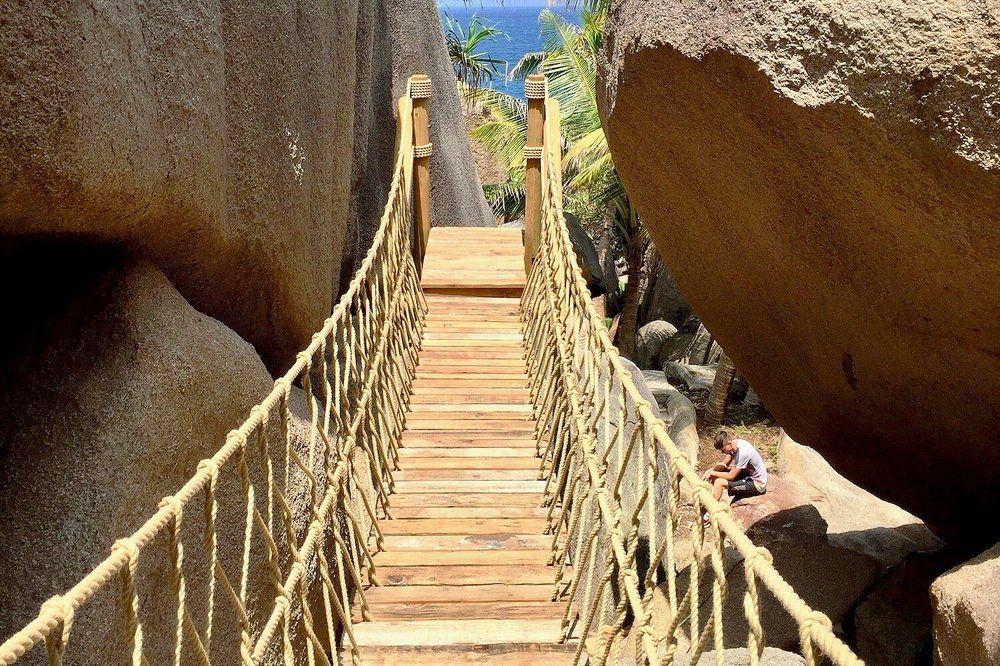

"We work with Treehouses, Rope Bridges and rope-work balustrades internationally, as such designing and looking for very specialist production of stainless steel fixings suitable for marine environments. On a search for threaded inserts, we were delighted to discover Bon Precision and on enquiry became very excited that we were dealing with not only a supplier but an expert company who could design, fabricate and test very specialist requirements.We had a huge quantity order for a project in the Middle East, the team at Bon Precision engaged fully and immediately with the project, sent a range of samples and designed a bespoke solution to our specific requirement. Our customers demand world-class quality and certification plus the ability to respond to bespoke and crafted requirements. Our projects worldwide are hugely supported by the first-class service and commitment given by Bon Precision.”

D&M Tech have worked with Bon Precision Engineering on several projects. They have produced a variety of CNC turned components for us, with fast turnaround times and excellent communication. We were particularly impressed when you managed to turn a component to 0.46mm diameter for a complex component. We’ve found Bon Precision Engineering to be very knowledgeable, helpful and easy to work with.